WORD SKATEFACTORY BAD RAGAZ

How we make your skatedecks?

Step 1

The Wood

Only finest Hard Rock Maple from Canada and North America will give the stiffnes, hardness and pop for your deck.

All other wood does not work!

Top and bottom plies are sanded, the wood plies are natural or colored in few colors.

Step 2

Pressing

Good wood needs good glue!

For our Swiss Handmade Decks we use a Swiss glue. The boards are cold single pressed. That means one deck in the mold, no heat! Heat makes the decks crispy and not that, that you want!

Step 3

Drilling

Trucks need holes!

After glueing and pressing the plies, the boards needs holes for the trucks. With a special drilling machine we make the holes, the holes must be very exatly be drilled, otherwise you have fuckup holes in your deck. We have different wheelbases. The wheelbases depends on the width of the

Step 4

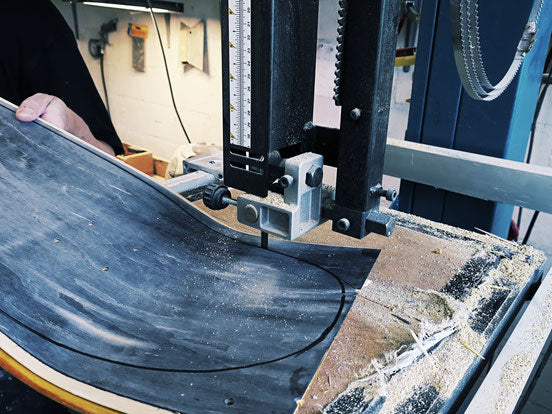

Cutting

This step will make from a uncutt deck a cruiser, street deck, oldschool deck...

We have many different shapes from 7.5 up to 9.0 inch. If requested we can produce custom shapes.

Step 5

Sanding

Smoth and round edges.

After shaping the deck we rounding and sanding the edges, if glue spots on the deck they can sanded out.

Step 6

Painting

Sanded and polished decks needs laquer.

Our Swiss laquer protect the deck against moisture and we need this underground for the printing.

Step 7

Shrinking

All finished decks will be packed with a big shrinking machine.

Stickers and flyers can packed also with the board.

The shrink wrapping protect the deck and the grafics.